Diamond Sourcing

Ethical and Responsible Sourcing: Diamonds are obtained from reputable suppliers who adhere to ethical and responsible mining practices, ensuring transparency and accountability.

Quality Assurance: Rigorous screening processes are in place to verify the authenticity and quality of sourced diamonds, guaranteeing their legitimacy and value.

Planning and Analysis

Expert Evaluation: Skilled gemologists meticulously assess each diamond, considering factors such as size, shape, and internal characteristics to optimize its potential.

Precision Planning: Detailed planning ensures that the diamond is cut and shaped to maximize its beauty and value, taking into account market trends and customer preferences.

Diamond Sawing

Customized Cutting: Diamonds are sawn into rough shapes tailored to their individual characteristics and intended final designs, ensuring optimal utilization of material.

Advanced Machinery: High-precision sawing machines equipped with diamond-tipped blades are used to cut diamonds with accuracy and efficiency, minimizing loss and maximizing productivity.

Advanced Machinery: High-precision sawing machines equipped with diamond-tipped blades are used to cut diamonds with accuracy and efficiency, minimizing loss and maximizing productivity.

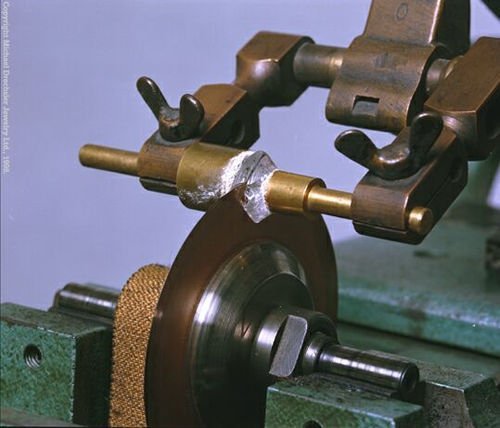

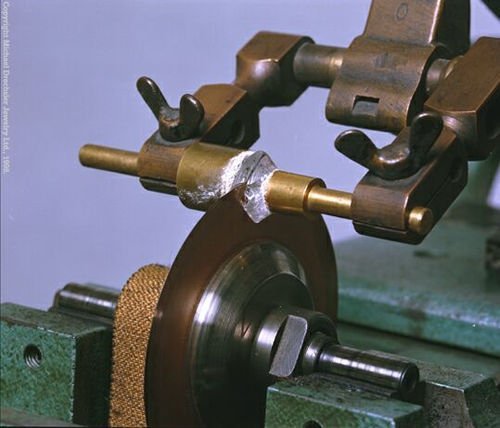

Diamond Bruting

Forming the Girdle: Diamond bruting involves shaping the rough diamond into a rounded form, creating the girdle—the outer edge of the diamond that defines its shape and proportions.

Symmetry and Balance: Skilled artisans meticulously grind and shape the diamond to achieve symmetry and balance, laying the foundation for the faceting process.

Diamond Faceting

Precision Cutting: Each facet is carefully cut and polished to precise angles and proportions, maximizing the diamond's brilliance, fire, and scintillation.

Artistic Craftsmanship: Highly skilled artisans apply their expertise and craftsmanship to bring out the diamond's natural beauty, creating dazzling displays of light and color.

Diamond Grading

Standardized Evaluation: Diamonds are graded according to internationally recognized standards, such as those established by the Gemological Institute of America (GIA), ensuring consistency and accuracy in assessment.

Comprehensive Analysis: Trained gemologists assess the diamond's cut, color, clarity, and carat weight, providing detailed reports that serve as valuable reference points for buyers and sellers.

Quality Control

Stringent Standards: Quality control measures are implemented at every stage of the manufacturing process to uphold the highest standards of craftsmanship and integrity.

Continuous Improvement: Feedback mechanisms and quality assurance protocols are in place to identify areas for improvement and ensure ongoing excellence in diamond production.